Understanding NEMA Connector Charts

NEMA connector charts provide crucial information for identifying and selecting electrical plugs and receptacles. These charts detail voltage, amperage, and configuration details, ensuring proper device compatibility and safe electrical connections. Understanding these charts is essential for various applications.

Decoding NEMA Designations

NEMA designations, found on connector charts, follow a standardized format to quickly convey key electrical characteristics. A typical designation, like “5-15R,” is broken down as follows⁚ the initial number (5 in this case) indicates the voltage rating (125V for 5, 250V for 6). The number after the hyphen (15) represents the amperage rating (15 amps). Finally, the letter (R) signifies the type of connector, with “R” denoting a receptacle (female) and “P” representing a plug (male). This concise system allows for easy identification and selection, preventing compatibility issues. Different charts might include additional designations for specialized connectors or locking mechanisms, but the core principles remain consistent. Always refer to the complete chart for a comprehensive understanding of all possible configurations and ratings. This ensures safe and correct electrical connections are made. Understanding these codes is vital for both electricians and end-users to avoid potential hazards and ensure proper functionality.

Identifying Plugs (P) and Receptacles (R)

NEMA connector charts clearly distinguish between plugs (P) and receptacles (R), a crucial aspect for ensuring correct pairings. The “P” designation always indicates a plug, the male connector with prongs designed to insert into a receptacle. Conversely, “R” signifies a receptacle, the female connector with slots or holes that accept the plug’s prongs. This simple yet essential distinction is consistently maintained throughout NEMA charts, regardless of voltage or amperage ratings. Mismatching plugs and receptacles can lead to unsafe conditions and equipment malfunction. The charts provide visual representations alongside the alphanumeric codes, further clarifying the difference. Understanding this fundamental distinction is paramount before connecting any electrical device. Always cross-reference the plug and receptacle designations to guarantee compatibility and prevent potential electrical hazards. Careful attention to these details ensures safe and reliable electrical connections.

Amperage and Voltage Ratings

NEMA charts clearly display amperage and voltage ratings, critical for safe electrical connections. Amperage, measured in amps, indicates the maximum current a connector can safely handle. Voltage, measured in volts, specifies the electrical potential difference. These ratings are essential for matching electrical devices to appropriate outlets; using a connector with insufficient amperage or voltage can lead to overheating, damage, or even fire. NEMA charts list these ratings prominently for each connector type, often using a two-part code where the numbers before the dash often, but not always, represent the amperage. For instance, a “5-15R” receptacle indicates a 15-amp rating at 125 volts, while a “6-20R” signifies a 20-amp rating at 250 volts. Careful attention to voltage and amperage ensures that the connector’s capacity meets or exceeds the electrical device’s requirements, preventing overload and ensuring safe operation. Always consult the chart to ensure that both amperage and voltage match the appliance’s specifications before making a connection.

NEMA Connector Chart Types

NEMA connector charts categorize connectors into distinct types based on their design and application. Common types include straight blade, locking, and specialty connectors, each with unique configurations and purposes.

Straight Blade Connectors

Straight blade NEMA connectors are the most common type, found in everyday household and industrial applications. These connectors feature parallel blades that insert directly into matching receptacles. The charts clearly illustrate the arrangement of these blades, differentiating between various amperage and voltage ratings. For example, a 5-15R receptacle (15 amps, 125V) will have a different blade configuration compared to a 6-20R (20 amps, 250V). Understanding the pin configuration is crucial for safe and correct connections. Mismatched connectors can lead to electrical hazards or equipment malfunction. The charts typically represent these configurations with clear diagrams, showing the number of blades, their size and spacing, and the position of any grounding pins; This visual representation simplifies the identification process, even for those unfamiliar with electrical terminology. Always refer to the appropriate NEMA chart to ensure compatibility before making any connections.

Locking Connectors

Unlike straight blade connectors, locking NEMA connectors incorporate a mechanism to secure the plug and receptacle, preventing accidental disconnections. These are often used in situations where vibration or movement might compromise a connection’s integrity, such as industrial machinery or outdoor settings. The locking mechanism usually involves a twist-lock, cam-lock, or other similar design. NEMA charts for locking connectors will illustrate these locking features, often showing the locking mechanism’s orientation and engagement points. These charts also specify the amperage and voltage ratings specific to the locking connector type. For instance, L5-15R and L5-15P represent a locking configuration with a 15-amp, 125V rating, distinct from its non-locking counterpart, the 5-15R/P. Detailed diagrams and specifications are included to help users correctly identify the plug and receptacle type and ensure the proper connection. Always carefully examine the chart’s illustrations to confirm the correct locking mechanism and associated electrical specifications before plugging in equipment.

Specialty Connectors

Beyond standard straight blade and locking connectors, NEMA charts may also include entries for specialty connectors designed for specific applications or environments. These often cater to unique voltage, amperage, or physical requirements. Examples include connectors designed for harsh environments with increased resistance to water ingress or extreme temperatures, often found in industrial or outdoor applications. Other specialty connectors might have unique pin configurations for specialized equipment or incorporate features like built-in fuses or circuit breakers for added safety. These variations often have specific alphanumeric designations within the NEMA system, clearly identified in the chart. For example, a connector designed for high-frequency applications or those with a particular grounding scheme will be distinct from standard configurations. Consult the chart’s detailed diagrams and specifications for these less common types. Understanding the nuances of these specialty connectors is crucial for ensuring compatibility and safety in non-standard electrical setups, preventing potential hazards associated with improper connections.

Utilizing NEMA Charts for Specific Applications

NEMA charts are indispensable tools for matching electrical equipment to appropriate power sources. Correct connector selection prevents damage and ensures safe operation, crucial for diverse applications.

Choosing the Right Connector

Selecting the correct NEMA connector is paramount for safe and efficient electrical connections. Begin by identifying the voltage and amperage requirements of your device. This information is typically found on the device’s label or in its user manual. Next, consult a NEMA connector chart to find a connector with matching specifications. The chart will show the various NEMA designations, such as 5-15P or 6-20R, which indicate the voltage, amperage, and configuration of the plug and receptacle. Pay close attention to the number of poles and wires, as well as the presence of a grounding pin. Ensure that the connector’s amperage rating is equal to or greater than the device’s requirements. Using a connector with insufficient amperage can lead to overheating and potential fire hazards. Conversely, using a higher-amperage connector is generally acceptable, provided it is physically compatible with the receptacle.

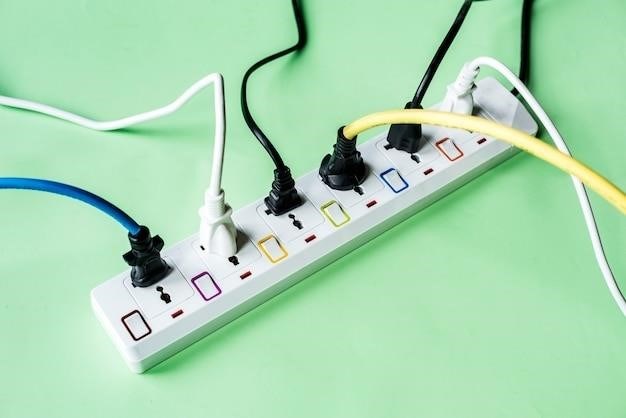

Troubleshooting Compatibility Issues

Compatibility problems with NEMA connectors often stem from mismatched voltage, amperage, or physical configurations. If a plug doesn’t fit into a receptacle, consult a NEMA chart to verify their designations. A mismatch in voltage (120V vs. 240V) is a significant safety hazard and necessitates immediate attention. Never attempt to force a plug into an incompatible receptacle. Incorrect amperage can lead to overheating and potential fire. Ensure the connector’s amperage rating meets or exceeds the device’s requirements. If the plug appears physically compatible but doesn’t function, check for loose wiring or damaged components on both the plug and receptacle; A faulty ground connection can also cause issues and should be inspected carefully. If troubleshooting proves unsuccessful, consult a qualified electrician for assistance, especially if dealing with higher voltages or amperages. Remember, incorrect connector usage poses significant safety risks.